The Revolutionary Vapor Blasting Machine: A Game-Changer in the World of Gadgets

In the ever-evolving world of gadgets, advancements are constantly being made to improve efficiency and performance. One such innovation that has garnered significant attention is the vapor blasting machine. This cutting-edge technology has revolutionized various industries, offering unparalleled benefits that traditional methods simply cannot match. In this blog post, we will explore the incredible capabilities and applications of vapor blasting machines and how they are transforming the way we approach surface preparation and cleaning tasks.

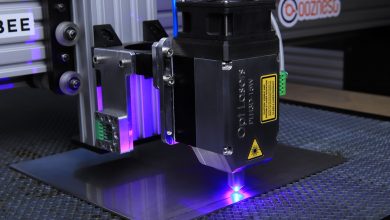

What is a Vapor Blasting Machine?

A vapor blasting machine, also known as a wet blasting machine or slurry blasting machine, is a state-of-the-art device that combines abrasive media with water to achieve exceptional cleaning and finishing results. The process involves propelling a mixture of water, fine abrasives, and compressed air at high speeds onto the surface to be treated. This action creates a gentle, non-destructive impact, removing contaminants, rust, old paint, and other unwanted elements while leaving the underlying material intact. The result is a smooth, clean surface with an even finish, making it ideal for a wide range of applications across various industries.

Applications in Industrial Cleaning

Vapor blasting machines have found extensive applications in industrial cleaning processes. From automotive restoration to aviation and marine maintenance, this technology has become a go-to solution for professionals seeking a high-quality, precision cleaning method. The gentle yet effective nature of vapor blasting allows for the removal of tough residues, grime, and corrosion from delicate surfaces without causing any damage. It proves especially valuable in restoring old machinery and equipment to their original glory, effectively extending their lifespan and saving on replacement costs.

Revolutionizing Surface Preparation

Surface preparation is a critical step in any coating or painting application, and vapor blasting machines have taken this process to a whole new level. Traditional abrasive blasting methods can be harsh on surfaces, leading to uneven coatings and subpar results. In contrast, the vapor blasting technique creates an ideal surface profile, allowing coatings and paints to adhere better, resulting in longer-lasting finishes with enhanced aesthetics and performance. Industries such as construction, aerospace, and manufacturing now rely on vapor blasting machines to achieve outstanding surface preparation.

Eco-Friendly Solution

The environmental impact of any technology is of growing concern, and vapor blasting machines address this issue head-on. Unlike some traditional blasting methods that produce harmful dust and waste, vapor blasting machines significantly reduce airborne particles and contain the waste within the water-based slurry. This eco-friendly approach makes them a preferred choice for environmentally conscious businesses seeking to minimize their carbon footprint while maintaining high standards of efficiency.

Versatility and Adaptability

One of the key advantages of vapor blasting machines is their versatility and adaptability. With adjustable pressure and various abrasive options, these machines can cater to a wide array of surface cleaning and finishing tasks. Whether it’s delicate restoration work on historical artifacts or heavy-duty cleaning in industrial settings, vapor blasting machines can be fine-tuned to deliver optimal results for any application.

Conclusion

In conclusion, the vapor blasting machine has emerged as a game-changer in the world of gadgets and industrial equipment. Its ability to provide precise, efficient, and eco-friendly cleaning and surface preparation solutions has positioned it as an indispensable tool across multiple industries. As technology continues to advance, we can expect further enhancements to the vapor blasting process, solidifying its place as a top choice for those seeking exceptional results without compromising on sustainability and performance.